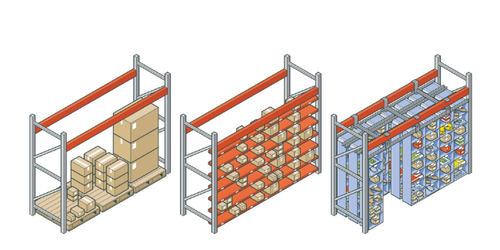

With 400,000+ sq. ft. of warehouse space and our 100+ acre yard, we can handle the largest warehouse racking jobs for supply or liquidation. We sell new or used pallet rack, wire deck, cantilever rack, pallet flow rack, carton flow rack, drive-in rack, push-back rack, mezzanine pick modules, conveyors, dock equipment and more.

American Material Handling can help you with your project from conception to completion. AMH will work with you to build a custom warehouse racking plan including layout planning, equipment selection, and pallet rack installation.

Whether your business is growing, relocating, downsizing, or closing, you will eventually have a decision to make regarding what to do with your existing equipment. Operational downtime considerations, lease expirations, and limited staffing resources are just a few of the things that can cause a sense of urgency and stress. AMH works to create solutions to save you time and money.

2 Step ErectaStep platform. 36″ x 36″ base with platform surface at 27″. Yellowgate Swing Gate adjustable from 16″ to 36″. Right hand or left hand swing. 3 Guardrails allowing for safe use of platform.

Request a FREE Quote Today!

Keep up with American Material Handling, new products, services, and industry news. Sign up today.